GARBAGE POWER

Design Works is currently a consultant to CBG as a start up company.

Carbon Black Global develops an eco-friendly, trash-to-energy plant for municipalities and natural disaster cleanup

RUNNING OUT OF ROOM – Facing limited space, many island governments around the world are struggling to find the best solution for their overcapacity landfills.

(Photo courtesy of Carbon Black Global)

Behind their scenic beaches, coral reefs, rainforests or volcanoes, many tropical islands face major environmental problems that are invisible on tourism websites but have a daily negative impact on native residents. Throughout the South Pacific , for example, islands have limited options for landfills and the ugly overflow is damaging the quality of life and polluting the ocean.

Frustrated residents have come up with their own solution: Burning household waste in large, open backyard pits.

“I’ve always wanted to live on a small South Pacific island,” says Earl Decker, Vice President and patent holder of Carbon Black Global . “I was surprised when the first time I visited the region, it seemed like every island was on fire.”

Based in Tennessee, Carbon Black Global specializes in designing and building customized manufacturing systems that convert waste materials into activated carbon and syngas , which can generate steam or electricity. Garbage does not need to be sorted – even diapers, tires and plastic bottles are processed with minimal ash – and clean power is generated without polluting the air. The company has generated interest from the governments of American Samoa and Tonga in the South Pacific, recently demonstrating how the technology can solve two problems at once.

According to Dr. Judi Krzyzanowski , a third-party environmental scientist hired to evaluate waste management proposals, installing a CBG trash-to-energy plant would reduce Tonga’s greenhouse gas emissions by more than 90 percent compared to conventional landfilling – with or without energy recovery from traditional incineration.

EXPLORING SOLUTIONS – Representatives of Carbon Black Global recently met with Tongan government officials to demonstrate the benefits of their waste-to-energy technology. From left to right: Sean Teo (CBG Tonga), Mark Fields (Evans Petree P.C – CBG Attorney/Council),Carl Sanft (Chairman of the Board, Tonga Power/Wastewater), Earl Decker (CBG Vice President), Robert Matthews (CEO, Tonga Power), Malakia L Sika (CEO, Tonga Waste Authority), Vincent Harkins (CFO, CBG), Mike Mentikov (President, CBG). (Photo courtesy of Carbon Black Global.)

“ We have also had some interest from several Caribbean islands both for hurricane debris and municipal waste,” says Decker. “And w e’re looking into mining existing landfills and pulling garbage back out of the ground to turn into clean energy. This is a problem everywhere around the world.”

Carbon Black Global’s technology has wide applications. Customers include food processors, textile factories, farms, hotels, shopping centers, petrochemical plants, and municipalities.

Decker says the U.S. military is also exploring the use of CBG mobile trash-to-energy systems for its forward operating bases, where electricity and waste management could be provided in an efficient, fast and environmentally responsible manner.

Real-Time CAD Collaboration

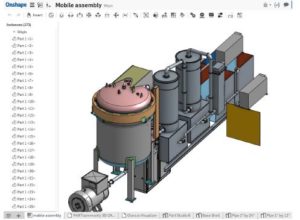

Carbon Black Global’s design team chose cloud-based Onshape, a modern CAD system that enables multiple engineers in different locations to collaborate in real time. The company was previously spending too much time coordinating between engineers using three different file-based CAD systems.

With its design team spread between multiple locations – Tennessee (Maffett-Loftis Engineering LLC), Georgia (Practical Steam), Washington (Designworks Ltd) and Ontario, Canada – Carbon Black Global chose Onshape, the full-cloud professional 3D CAD system that enables multiple team members to simultaneously work on the same model.

“If we change one part, the entire team can see it right way. There’s no confusion over what version of the design we’re working on,” Decker says. “That was one of the keys for us to adopt Onshape. If a colleague wants to make a change, I say, ‘yeah, go ahead!’ and we both see it happen.”

“That’s all I think about is continuous improvement,” he adds. “How can I make this better? What if I do this? Using Onshape’s comprehensive edit history , all the changes are automatically tracked for me. I can go back to any of my old parts, make a change, flip it into a diagram, share the PDF and it’s done. It’s just incredibly fast.”

Before adopting Onshape, CBG’s design team was like a CAD Tower of Babel with various partners coming in with their own preferred systems. “I was using AutoCAD, one of my engineering consultants was working in SOLIDWORKS and another engineering firm was using Pro/ENGINEER. We struggled for a while using all these different systems, and to be honest, it was a real pain in the neck,” says Decker.

“Since switching over to Onshape, I’d say we’re easily saving hours a day. I was working with three different drawings and it would take me a day to import them and get them in the right places,” he adds. “Onshape’s very intuitive so there was a very quick learning curve.”

CAD Anytime, Anywhere

Decker says he also appreciates the flexibility of being able to create and edit Onshape models on his tablet, versus traditional CAD systems which only provide mobile viewers. “Being able to;pull up a project on my tablet and flip through some of the iterations and say, ‘Hey, what about this?’ is extremely valuable. It offers you immediate access to your work if you’re off-site or in a meeting.”

“If I’m with one of the engineering guys and we’re looking at a scrubber, I can pull up the model and talk about a part like the spray nozzle and say, ‘This is what I’m talking about that’s inside this.’ It’s a significant capability to be able to carry that information around with you and have it at your fingertips,” Decker adds.

“I have a special laptop that I used only for AutoCAD. It would take up so much memory that I kept the rest of the computer clean just so it could run smoothly,” he says. “Now that I’m using Onshape on my tablet, my laptop stays on a shelf. I don’t actually use it.”

“We Are All Islands”

“I’m very excited to see what kind of difference we can make,” says Decker. “Right now, some of these small island countries are spending more than 10% of their gross domestic product on diesel fuel. Waste-to-energy plants can not only cut oil consumption and costs in half, but all that money will go straight back into the local economy.”

“Trash is becoming a big deal everywhere, not just on islands,” he adds. “Go and try to find a new landfill these days. Just about everybody is considered an island. Try to ship your garbage out of state. Try to ship it out of town. Nobody wants it.” “Now, if we can process it properly and deal with climate change at the same time, it doesn’t get any better than that,” Decker says. “It feels good to be on the right side of things.”

–END–